- Leadership Development

- Operational Excellence

- Industry 4.0 – Management Digitalization

- Food & Bev

- Construction

- Manufacturing

- Heavy Industry

- The Manager's Journey

- Cross-platform tool

- Digital Gemba Walk

- Collaboration and Rituals

- Coaching and Improvement

- Knowledge Center - New

- All Features

- Industry 4.0 and 5.0

Case Studies

- Continuous Improvement

- Frontline Managers

- Key Behaviroral Indicators

- Management Skills

- Productivity

- Free Resources

TABLE OF CONTENT

Share this article, download a pdf version., subscribe to our newsletter, 10 effective problem-solving methods and tools for manufacturers.

Downloaded on: September 5, 2024

• April 30, 2024

Variability of demand, quality management, equipment maintenance, and integration of new technologies : problems are frequent and inevitable, and manufacturers face challenges very often. Acknowledging this reality enables teams to remain vigilant, quickly identify and resolve these difficulties, and constantly improve processes and products alike.

Why focus on problem-solving? In the Lean philosophy , a problem isn't just a problem; it's also, and above all, an opportunity to do better. Rather than hiding or ignoring what's not working, the idea is to face up to it, to find structured methods for optimizing efficiency and quality. For this, there are a number of possible solutions and tools available.

What are the different stages of problem-solving? Which methods and tools are most effective in production environments? And how do you use them?

This article provides all the answers and problem-solving tips.

Key takeways:

- By scrutinizing every action and aspect of processes, it is crucial to distinguish between activities that bring value and those that don't , in order to reduce or eliminate waste.

- Involving employees in identifying problems and suggesting solutions strengthens their sense of ownership, and improves team cohesion and efficiency.

- Root Cause Analysis (RCA) helps to identify the underlying causes of problems to find more sustainable solutions and prevent problems from recurring.

- The use of tools such as the PDCA cycle and the 5S method, as well as techniques such as Six Sigma , is essential for optimizing processes and improving quality and efficiency.

- It is essential to monitor implemented changes and continuously improve them to maintain and increase Overall Equipment Effectiveness (OEE).

In a hurry? Save this article as a PDF.

Tired of scrolling? Download a PDF version for easier offline reading and sharing with coworkers.

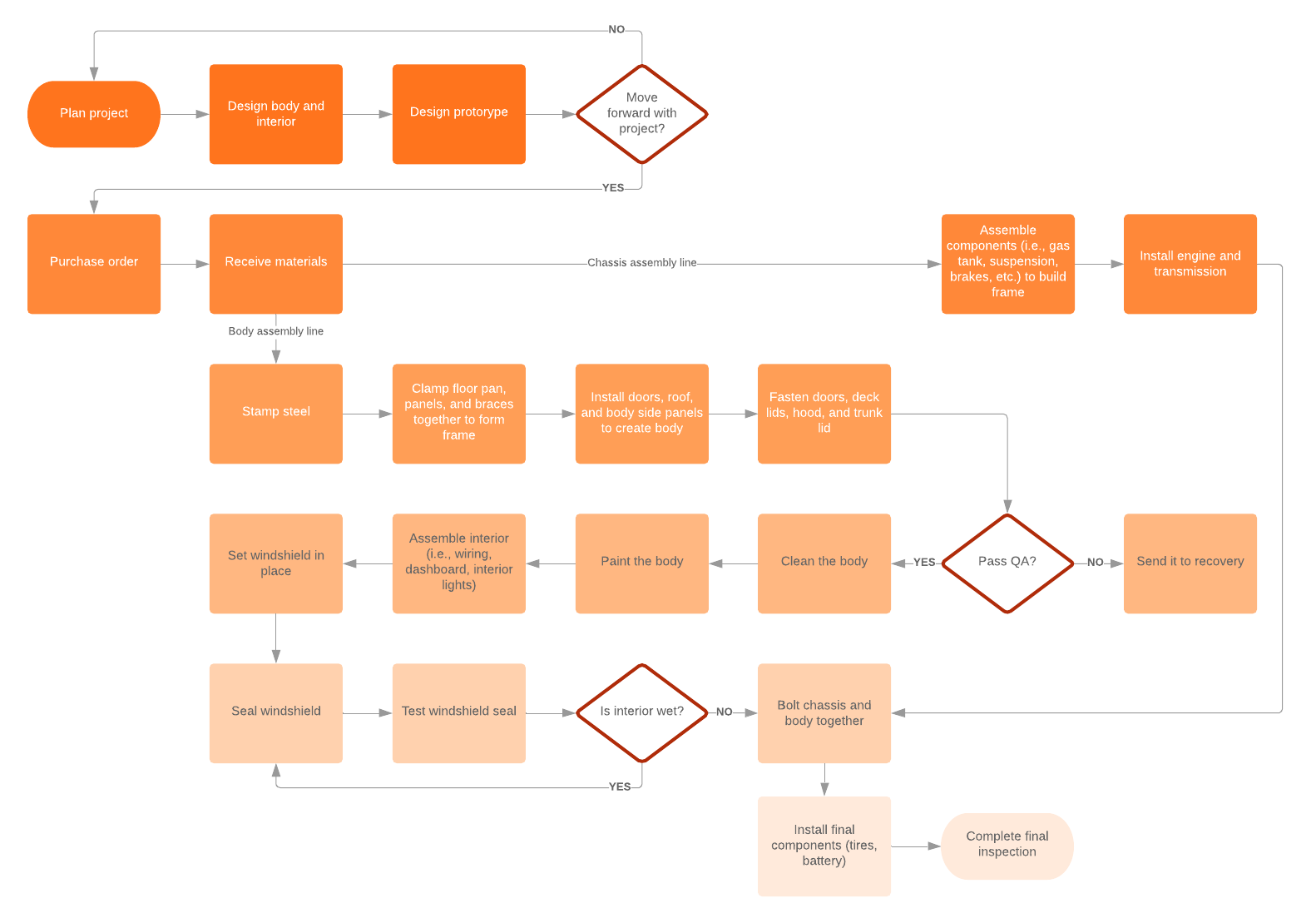

Key steps of a problem-solving process in a factory

To better understand each of these steps, let's take the example of a factory manufacturing automotive components, faced with a sudden rise in the number of defective parts.

1. Identify the problem

The first step is to recognize that a problem exists. This involves observing the symptoms and identifying the gaps between the current state and the desired goal.

The 5 Ws and H tool enables you to identify the problem by collecting factual information on incidents.

- Observation: Abnormal increase in the number of defective parts at the quality inspection station.

- Action: Collect data on the number of defective parts, the types of defects, and the times when they occur.

2. Define the problem

After identification, you need to precisely define the problem. This involves determining its scope (using the Four A’s method, for example), representing it clearly, and understanding its impact on operations.

- Analysis: 10% of parts produced have surface defects (higher than the acceptable standard of 2%).

- Action: Clearly define the problem as a significant increase in surface defects on automotive parts.

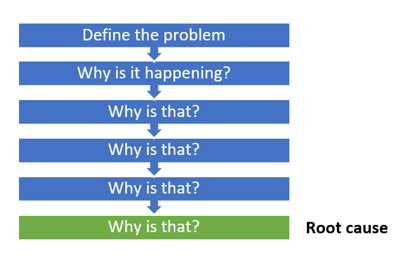

3. Find the root cause of the problem

This step aims to analyze the factors contributing to the problem in order to identify its root cause. This is a critical process requiring in-depth examination to avoid treating symptoms alone.

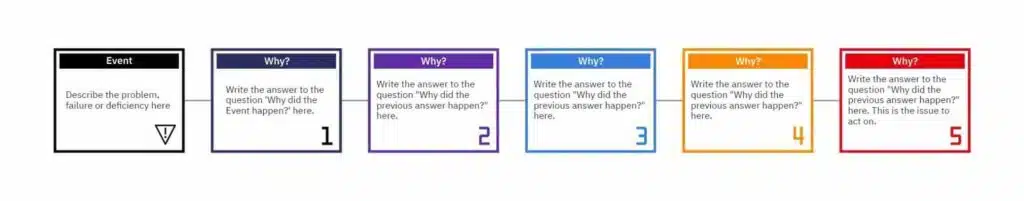

- Investigation: After using the 5 Whys method, the root cause turns out to be premature machine wear.

- Action: Examine maintenance records and machine operating parameters to confirm this cause.

4. Brainstorm solutions

Once the root cause has been identified, it's time to focus on finding solutions. This phase encourages creative problem-solving and innovation from the whole team. They have to explore existing ideas and generate new ones.

- Brainstorming: Several potential solutions are considered, such as replacing tools more frequently or modifying machine parameters.

- Action: Evaluate the advantages, disadvantages, and feasibility of each solution using the PDCA method.

5. Test your solutions

Before implementing a solution on a large scale, it is essential to test it in a controlled environment. This enables you to assess its effectiveness in real-life situations and adjust the action plan.

- Experimentation: Replace tools more frequently to see if this reduces the defect rate.

- Action: Implement the test plan over a set period using the "Do" phase of PDCA, then collect data on the impact of this change.

6. Standardize and document the chosen solution

Once you’ve found the best solution, it must be standardized and integrated into the organization's procedures. Documenting the process helps prevent the problem from recurring and facilitates employee training .

- Implementation: After confirmation that more frequent tool replacement reduces defects, this practice is standardized across the entire production line using the DMAIC method .

- Action: Document the new process using the 8Ds, train operators in the new practice, and integrate the change into standard operating procedures.

5 Useful problem-solving strategies for manufacturing

1. 8d (eight disciplines problem solving).

8D is a quality approach to solving complex problems requiring in-depth analysis and lasting corrective action.

The method comprises eight steps:

- Prepare the 8D process

- Describe the problem

- Identify and implement immediate actions

- Identify the real causes

- Identify and implement permanent corrective actions

- Validate permanent corrective actions

- Prevent recurrence

- Congratulate the team

Use case in the manufacturing industry

Problem: Recurrent failure of a major piece of equipment, leading to costly production stoppages.

8D would enable a multi-disciplinary team to systematically identify, analyze, and eliminate the root cause of the failure while implementing sustainable corrective actions.

2. PDCA (Plan-Do-Check-Act)

Also known as the Deming wheel, this systematic, iterative model comprises four stages or cycles: Plan, Do, Check, Act.

The PDCA method helps companies test changes under controlled conditions, evaluate the results, and then implement improvements progressively to optimize production and ensure consistent product quality.

Problem: Variation in the quality of the finished product, which does not always meet standards.

PDCA would address this problem by planning improvements, testing them, evaluating their effectiveness, and adjusting the production process to stabilize product quality.

3. DMAIC (Define, Measure, Analyze, Improve, Control)

This Six Sigma method is highly effective in optimizing production processes, reducing variation, and eliminating defects by focusing on data and statistical analysis.

It involves clearly defining the problem (Define), measuring (Measure), and analyzing process data to identify root causes (Analyze), then implementing improvements (Improve) and controlling processes to ensure sustainable quality gains (Control).

Problem: High scrap and rework rates on an assembly line.

DMAIC would be used to specify the problem, measure performance, analyze data to find the cause, implement improvements, and control the process to reduce defects.

4. QRQC (Quick Response Quality Control)

This fast, effective method inspired by Lean Management, consists in identifying, analyzing and solving problems directly on the shop floor. It is particularly well suited to fast-paced production environments where immediate detection and resolution are necessary to maintain production continuity and efficiency.

Problem: Frequent safety incidents in the workplace.

QRQC would enable rapid reaction to identify and resolve the causes of such incidents immediately, thereby reducing their frequency and improving overall safety.

5. Four A’s

The Four A’s method is a structured approach that is designed to systematically address and solve problems within an organization.

- Assess: This step involves identifying and understanding the problem.

- Analyze: Once the problem is assessed, the next step is to analyze it to find the root causes.

- Address: With a clear understanding of the root causes, the third “A” involves developing and implementing solutions to address these causes.

- Act: The final “A” focuses on standardizing the correct solution and integrating it into the organization’s processes.

It is used where problems need to be solved quickly and efficiently while ensuring that lessons learned are integrated into standard practices.

Problem: Missed delivery deadlines due to production bottlenecks.

The Four A’s method would help to quickly detect bottlenecks, analyze their causes, find and implement effective solutions, and then integrate these changes into regular operations to improve on-time delivery.

How to choose the right problem-solving method

The choice of problem-solving method depends on several factors:

- The nature and complexity of the problem: Before choosing a problem-solving approach, you need to understand exactly what is wrong. If it's a complex and multifactorial problem, structured, in-depth methods such as 8D or DMAIC may be appropriate. For more immediate or quality-related problems, QRQC or Four A’s may be more appropriate.

- Company objectives: Look at the big picture; align the method with your strategic objectives, such as improving quality, reducing costs, or increasing customer satisfaction. For example, DMAIC is often chosen for defect reduction and process optimization objectives.

- Available resources: Think about the resources you can allocate to problem-solving processes (time, skills, budget). For example, PDCA can be implemented more quickly when resources are limited.

- Team expertise and problem-solving skills: Use a method that matches your team's qualifications. Training may be required for more complex approaches such as DMAIC or 8D.

- The need for standardization and documentation: If documentation and standardization of processes are essential, opt for methods that integrate these aspects, such as 8D or DMAIC.

5 Tools for structuring your problem-solving methods

Now it's time for the problem-solving tools! These will help structure the process and keep it moving in the right direction.

1. The 5 Whys

This problem-solving technique, created by Toyota founder Sakichi Toyoda, involves asking the question "Why?" five times until the root cause of a given problem is revealed. It's a simple but powerful tool for finding root causes.

A factory has a problem with late delivery of finished products:

- Why is the plant experiencing delays in the delivery of finished products? Because the production of final units is often late.

- Why is the production of final units behind schedule? Because assembly takes longer than expected.

- Why does assembly take longer than expected? Because parts needed to complete assembly are often missing.

- Why are parts often missing? Because supplies regularly arrive late from the supplier.

- Why do supplies arrive late from the supplier? Because orders are placed too late, due to an inefficient procurement process.

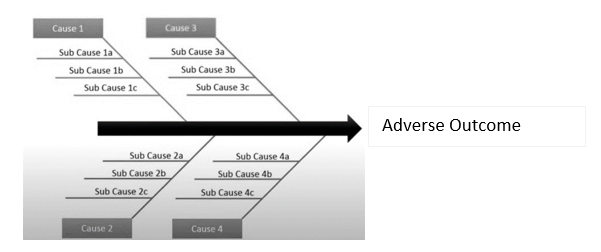

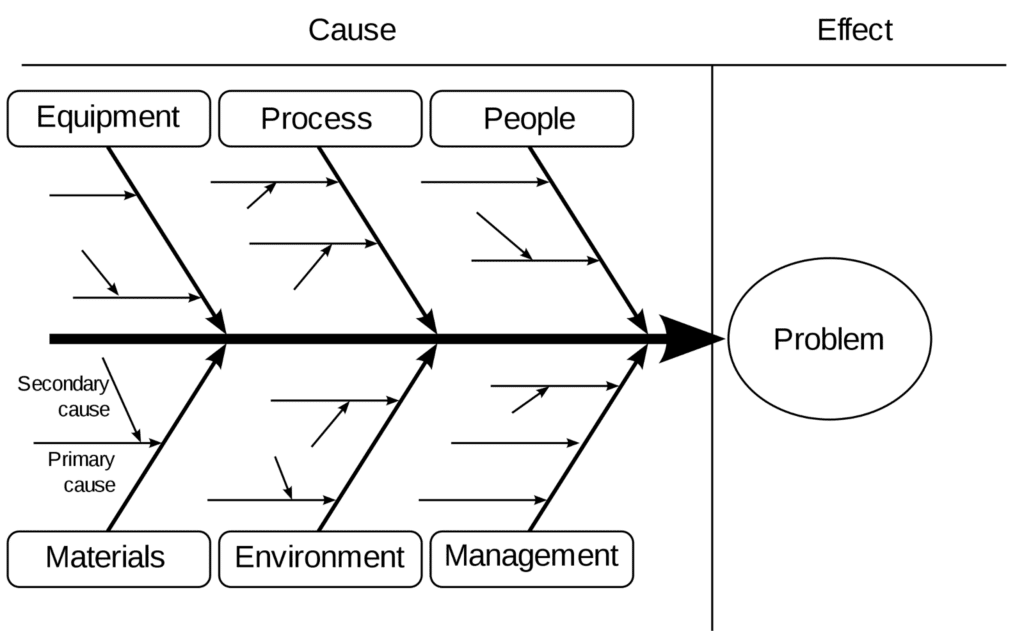

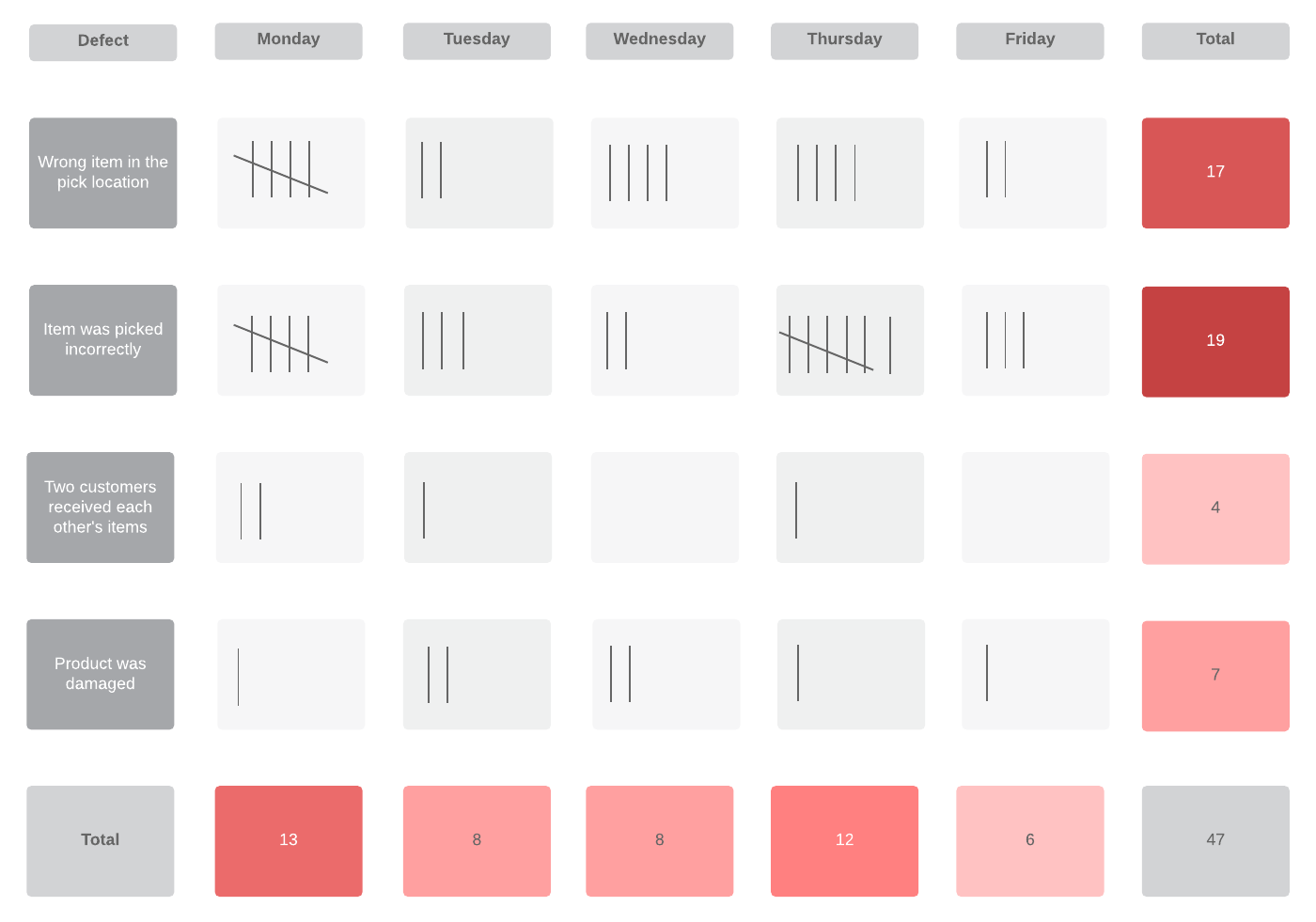

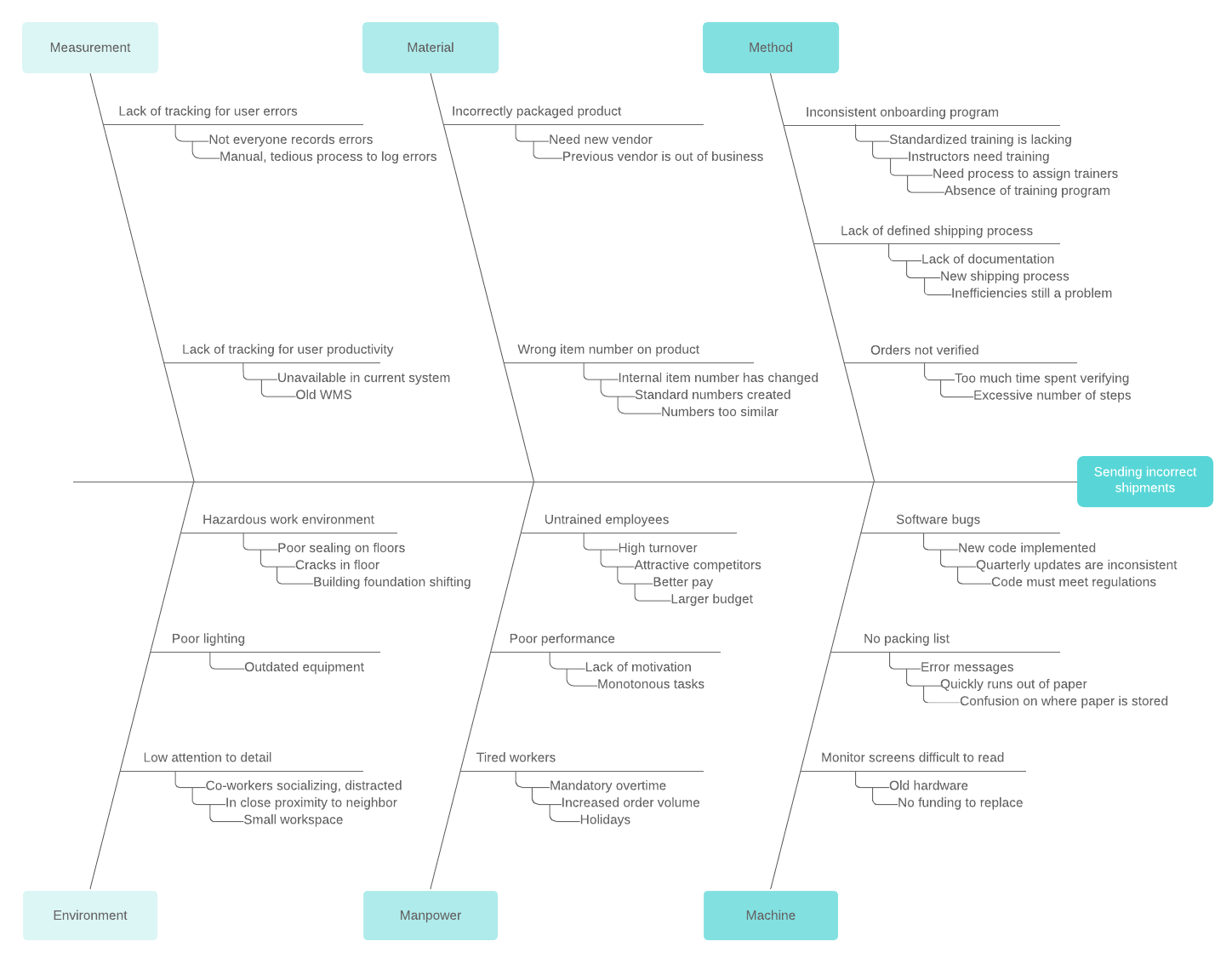

2. The Ishikawa diagram (5M)

Also known as the "fishbone diagram" or "5M", this tool developed by Kaoru Ishikawa helps to systematically visualize all the potential causes of a specific problem, as well as the contributing factors.

Causes are divided into 5 main categories.

A factory encounters a problem with a drop in product quality:

- Problem or "Effect" (fish head): Decline in product quality

- Categories of causes (main branches):

- Manpower: Operator skills , training, motivation.

- Methods: Work procedures, quality standards, operating instructions.

- Materials: Raw material quality, batch variability, supplier specifications.

- Environment: Working conditions, temperature, humidity, dust.

- Equipment: Equipment wear, machine calibration, maintenance.

This evolution of the Ishikawa diagram focuses on not five, but seven major problem areas: Manpower, Method, Materials, Environment, Equipment, Management, Measurement.

A factory is experiencing machine failure problems:

- Manpower: Inadequate operator training, human error due to fatigue, or lack of experience.

- Methods: Obsolete production processes, and lack of standardized operating and maintenance procedures.

- Materials: Inconsistent quality of raw materials, premature wear of spare parts.

- Environment: Unsuitable working conditions, disturbances due to excessive noise or vibration.

- Equipment: Outdated equipment, neglected or inadequate preventive maintenance.

- Management: Inadequate decision-making, and insufficient communication between departments.

- Measurement: Uncalibrated or faulty measuring instruments, lack of regular quality controls.

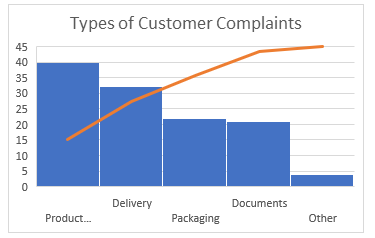

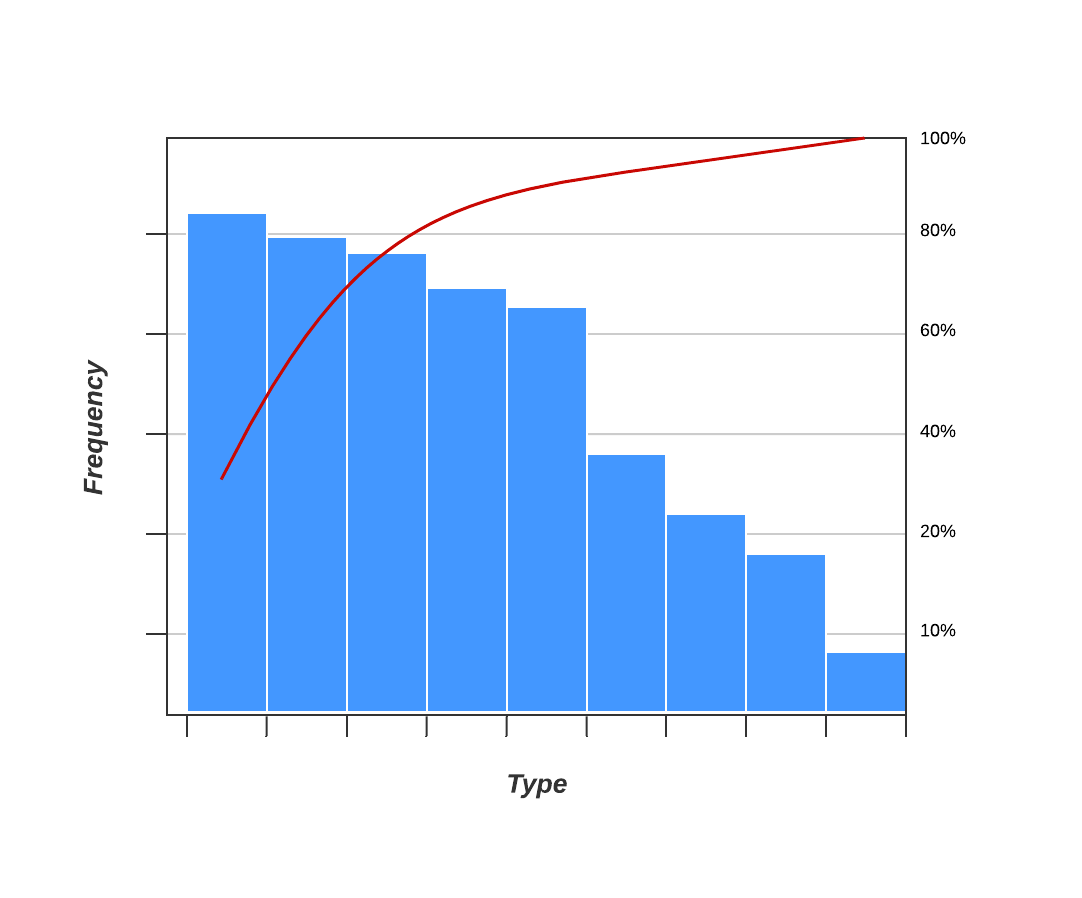

4. The Pareto principe

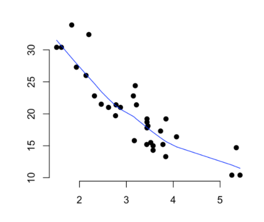

The Pareto or 80/20 principle is very useful for focusing on the problems that will have the greatest impact once solved, and for making informed decisions.

In a factory producing electronic components, 80% of production defects stem from just 20% of the manufacturing processes.

By analyzing production data, the company could discover that the majority of defects are linked to errors in the soldering and PCB inspection stages. These two stages, although representing a small part of the total manufacturing process, are crucial and require special attention to reduce the overall number of defects.

5. The 5 Ws and H

This tool helps gather comprehensive information on a problem by answering these key questions: Who, What, Where, When, Why, and How. Thus, it provides an in-depth understanding of the situation.

There is a delay in production at a furniture manufacturing plant:

- Who is affected by the problem? Assembly line operators and production managers are directly affected by the delay.

- What exactly is the problem? Deliveries of finished furniture to customers are several days behind schedule.

- Where exactly is the problem occurring? The problem occurs in the final assembly shop, where the furniture is prepared for shipment.

- When was the problem detected or when does it occur? The delay has been observed over the past two weeks, mainly during the third shift.

- Why does the problem occur? The problem could be due to inadequate staff planning and recurring packaging equipment failures.

- How does the problem occur? The delay is due to a bottleneck in the finishing and packing stage, where there is a lack of personnel and problems with the packing equipment.

Other tools can also be useful for structuring problem-solving methods:

- Brainstorming

- Gemba Walks

- SWOT analysis

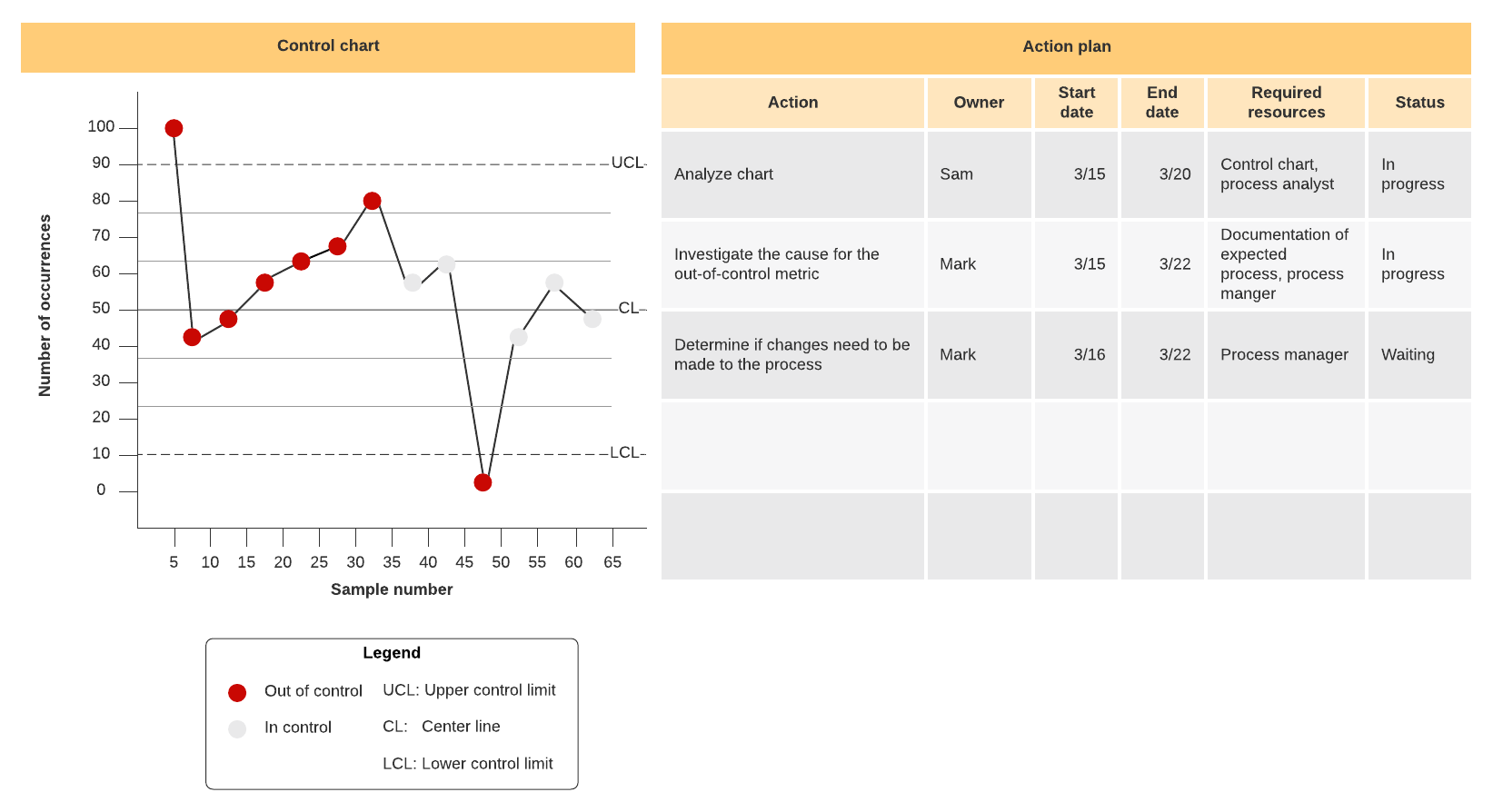

- Control charts

- Prioritization matrices

Tips for effective implementation of problem-solving techniques

Integrate problem-solving into daily routines.

Instead of seeing problem-solving as a separate activity, integrate it into daily routines. For example, set up SIM meetings to discuss ongoing problems as a group and monitor progress on solutions.

Use technology for your benefit

Adopt a Daily Management System (DMS) like UTrakk to quickly identify problems, track corrective actions, facilitate collaboration between teams, and document solutions in a centralized repository.

Develop specific key performance indicators for problem resolution

Define Lean KPIs that measure the effectiveness of the problem-solving process (average time to solve the problem, problem recurrence rate, and impact of solutions on business performance).

Practice problem-solving on the shop floor

To understand problems, you need to go where value is created. Encourage managers to go on the shop floor to directly observe processes, interact with operators, and identify possible improvements.

Create cross-functional problem-solving groups

Form teams with members from different departments to tackle complex problem-solving. Integrating different angles, perspectives, and expertise broadens the point of view on the subject, enriches the analysis, and generates more creative ideas.

Adopt a coaching approach to skills development

In addition to basic training, use mentoring and coaching to develop problem-solving skills . Experienced employees can guide less experienced ones, sharing their know-how.

Conduct post-mortem reviews

When a problem is solved, conduct a post-mortem to discuss what went well, what didn't, and how processes can be improved.

Tracking and evaluating each solution implemented allows you to adjust strategies as needed, learn from past experiences, and foster continuous improvement .

UTrakk: Your ally in structuring and optimizing problem-solving

Using organized methods and analytical tools to tackle challenges is essential for manufacturers seeking to improve operational efficiency and product quality. UTrakk DMS is the perfect solution for this structured approach to daily problem-solving. With its multiple functionalities – rituals, actions, dashboards, and more – this Daily Management System can adapt to any problem-solving method to optimize every step of the process. Once a solution is standardized, it can be documented in UTrakk’s Knowledge Center to ensure compliance and prevent recurrence.

Adopting these problem-solving techniques not only enables manufacturers to respond effectively to today's challenges, but it also lays the foundations for continuous improvement, ensuring their competitiveness in an ever-changing industrial environment .

FAQ on problem-solving methods

What are the key problem-solving methods for manufacturers.

The key problem-solving methods for manufacturers include Lean manufacturing, Six Sigma, and the PDCA (Plan-Do-Check-Act) cycle. These methodologies focus on eliminating waste, optimizing processes, and implementing continuous improvement to enhance operational efficiency.

How can manufacturers effectively implement Lean principles?

Manufacturers can effectively implement Lean principles by identifying and eliminating waste, optimizing workflows, and improving overall efficiency through techniques like Kanban and 5S. Training employees and involving them in the continuous improvement process are also critical steps.

What is the importance of Six Sigma in manufacturing?

Six Sigma is important in manufacturing because it provides a data-driven approach for reducing defects and variability in processes. This methodology helps in improving product quality and operational efficiency by following the DMAIC (Define-Measure-Analyze-Improve-Control) framework.

Can technology enhance problem-solving in manufacturing?

Technology plays a crucial role in enhancing problem-solving in manufacturing. Digital twins, augmented reality, and collaborative robotics are technologies that help improve precision, efficiency, and safety, facilitating better decision-making and process optimization.

What benefits do continuous improvement practices offer to manufacturers?

Continuous improvement practices offer several benefits, including increased operational efficiency, reduced waste and costs, and improved employee engagement and customer satisfaction. These practices encourage a proactive approach to addressing inefficiencies and fostering innovation.

Turn your production challenges into opportunities for improvement!

In addition to providing the UTrakk solution, Proaction International supports you in implementing the best problem-solving methods and helps you achieve operational excellence.

Adeline de Oliveira

Writer and editorial manager for about 15 years, Adeline is passionate about human behavior and communication dynamics. At Proaction International, she covers topics ranging from Industry 5.0 to operational excellence, with a focus on leadership development. This expertise enables her to offer insights and advice on employee engagement and continuous improvement of managerial skills.

Déli-Porc Develops an Agile, Digitalized Culture Focused on Optimization

Kefor maximizes its performance by optimizing manager skills, le goupe maurice: motivate and retain talents by focusing on the leadership development of managers.

© 2023 Proaction International Inc. All rights reserved. Terms of Use | Privacy Notice | Cookie Notice

Warning: The NCBI web site requires JavaScript to function. more...

An official website of the United States government

The .gov means it's official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you're on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- Browse Titles

NCBI Bookshelf. A service of the National Library of Medicine, National Institutes of Health.

StatPearls [Internet]. Treasure Island (FL): StatPearls Publishing; 2024 Jan-.

StatPearls [Internet].

Quality improvement methods (lean, pdsa, six sigma).

Emily Barr ; Grace D. Brannan .

Affiliations

Last Update: January 11, 2024 .

- Definition/Introduction

Quality improvement is integral to many sectors, including business, manufacturing, and healthcare. Systematic and structured approaches are used to evaluate performance to improve standards and outcomes. The Institute of Medicine defines quality in healthcare as “the degree to which health services for individuals and populations increase the likelihood of desired health outcomes and are consistent with current professional knowledge.” [1]

In healthcare, quality improvement methods are traced back to the 19 th century; 2 examples are the advocacy for handwashing in medical care by an obstetrician, Ignaz Semmelweis, and the betterment of living conditions and excessive mortality of soldiers in army hospitals to nurse Florence Nightingale. [1] Many quality improvement methods can be applied to healthcare, 3 of which include Plan-Do-Study-Act (PDSA), Lean, and Six Sigma. Each method has a unique goal-oriented outcome that has been applied to healthcare to streamline and optimize processes.

PDSA is a cyclical quality improvement method often compared to the application of the scientific method, differing from Lean philosophy due to its iterative format. [2] PDSA was adapted to healthcare in 1996 by statistician Gerald J. Langley and built upon its manufacturing origin in 1986 by statistician Edwards Deming. [2] PDSA focuses on 4 stages: plan, do, study, and act.

The first stage, plan, begins with identifying a project goal. The next stage, do, is a small-scale implementation of the plan applied to meet the goal. The scope or size is small to enable any pivots to be addressed promptly. The study stage compares predicted data outcomes to achieved data outcomes. The act stage combines data from the prior 3 stages into an improved executed plan. The 4 steps must be thought out and repeated for a refined process. PDSA is not a standalone method but utilizes other quality improvement tools and is a key component of the Model for Improvement.[ [2] [3] [4]

Lean stems from the Toyota Production System (TPS) and focuses on improving quality and productivity through efficient and value-added processes by eliminating 3 items: waste (muda), unevenness or inconsistencies (mura), and overburden or unreasonableness (muri). [5] [4] [6] [7] TPS, also called the “Toyota way,” is credited to Japanese engineer Taiichi Ohno. Its origin can be traced back to the Henry Ford assembly line and Toyota Motor Corporation production system in the 1950s, as they tried to increase value-added products or services—that is, entities customers were willing to pay for while decreasing extraneous products or services. [8]

Mura can be corrected by standardization to create dependability and reliability. Muri emphasizes creating a culture of problem-solving instead of blaming. Lean has identified 8 wastes or muda. [5] [6] Defects refer to work that needs modification, alteration, or repair. Overproduction is ordering unnecessary tests. [6] Waiting can be in the form of waiting for supplies, a turn to use a machine, to be seen by a provider, or for test results, to name a few. Unutilized talent refers to wasted people skills. Transportation may include transporting supplies from one area to another or moving patients from the hospital room to the laboratory for tests. An example of inventory is storing or buying excessive medical supplies, especially if they expire before usage. Unnecessary motion may include wasted movement for providers, caregivers, and patients. [6] Extra-processing denotes unnecessary steps or work.

5 overarching principles contribute to Lean methodology implementation: [9] [6]

- Identifying the value of a product or service to the customer, which could be the patient or another department in the hospital.

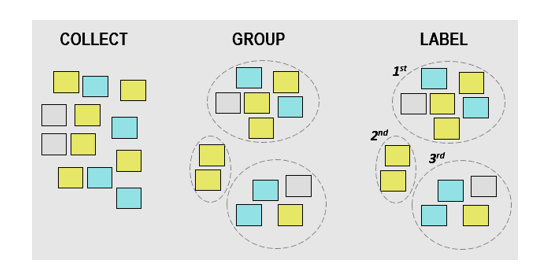

- Value stream mapping is a visualization method of processes, materials, the flow of information, and resources involved in creating a product or service to identify those that add value and remove those that are wasted. [5] [10] ]

- Creating flow by eliminating barriers.

- Establishing pull based on actual customer demand rather than forecasted demand.

- Establishing perfection means that in every system, efforts to eliminate waste are continuous and should always strive to meet or exceed customer or patient needs and satisfaction.

Core to Lean is Kaizen, a focused, team-centric, continuous, and rapid improvement endeavor to implement small changes into systemic, standardized improvement cycles. The understanding of Kaizen is reflected in its etymology, derived from the “Japanese words “kai,” meaning change, and “zen,” meaning good.” [11] [7]

Lean uses different tools to achieve its goals. 5S refers to sorting, setting in order, shining, standardizing, and sustaining elements required to sustain a clean, orderly, and organized workplace. [10] Just-in-Time (JIT) refers to supplies being available when needed. [12] This is feasible if there is consistency and uniformity in the system, which allows predictability and control. JIT works in tandem with Kanban or the inventory system, which relies on supplies approval and documentation. A3 is a visual and structured tool that identifies problems and solutions using an A3-sized or 11 x 17 inches paper. [13]

Like Lean thinking, Six Sigma is a methodology focused on optimizing performance, controlling, and decreasing variability. [14] [4] Six Sigma techniques were developed in the ’80s by Motorola. [15] Six Sigma is derived from a statistical concept of 6 standard deviations from the mean or 3.4 defects per million units. [16] Six Sigma often focuses on quantitative healthcare analysis to refine delivery efficiency while increasing patient safety.

Six Sigma is different from other methodologies in that it is focused on financial outcomes and statistical outcomes and requires management support. [15] Leadership support is needed to set the goals for Six Sigma initiatives and train or hire specific personnel in the form of “Belts” as part of the more formalized quality management structure. [17] The “Belts” signify training and project involvement levels and usually require certification. [17] A Master Black Belt is the most experienced, trains the other belts, and is the project consultant. Black Belts leads the execution of the Six Sigma projects. Green Belts leads project implementation under the guidance of Black Belts, and Yellow Belts participates as a member in projects. [17]

Six Sigma employs 2 methods: [17] [14] [8] [4]

- DMAIC or Define, Measure, Analyze, Improve, and Control. DMAIC is used for improving current processes.

- DMADV or Define, Measure, Analyze, Design, and Verify. DMADV is employed when developing new processes and products.

Different well-known quality improvement tools are used within the different phases of DMAIC or DMADV. Here are a few examples: [18] [19] [20] [21]

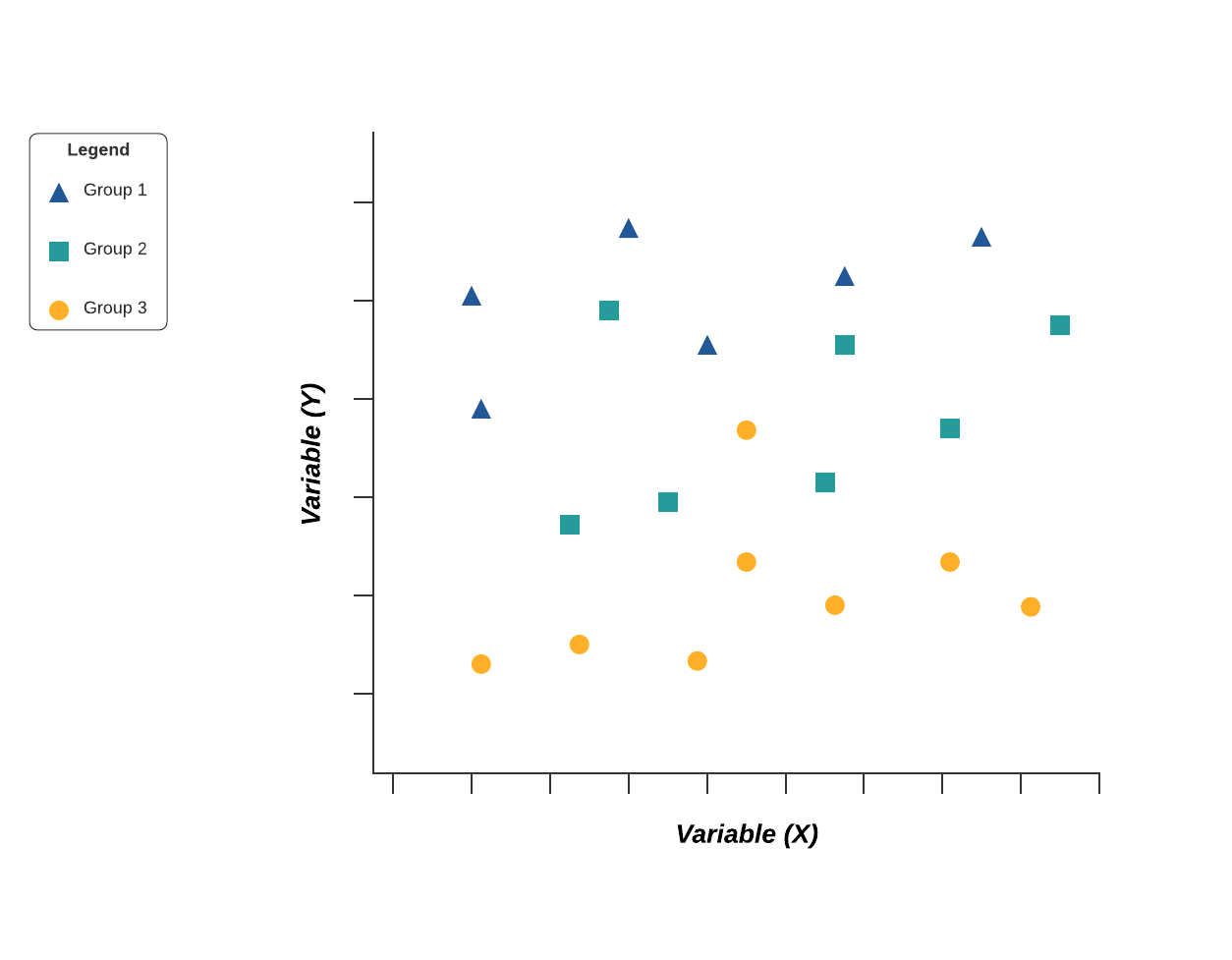

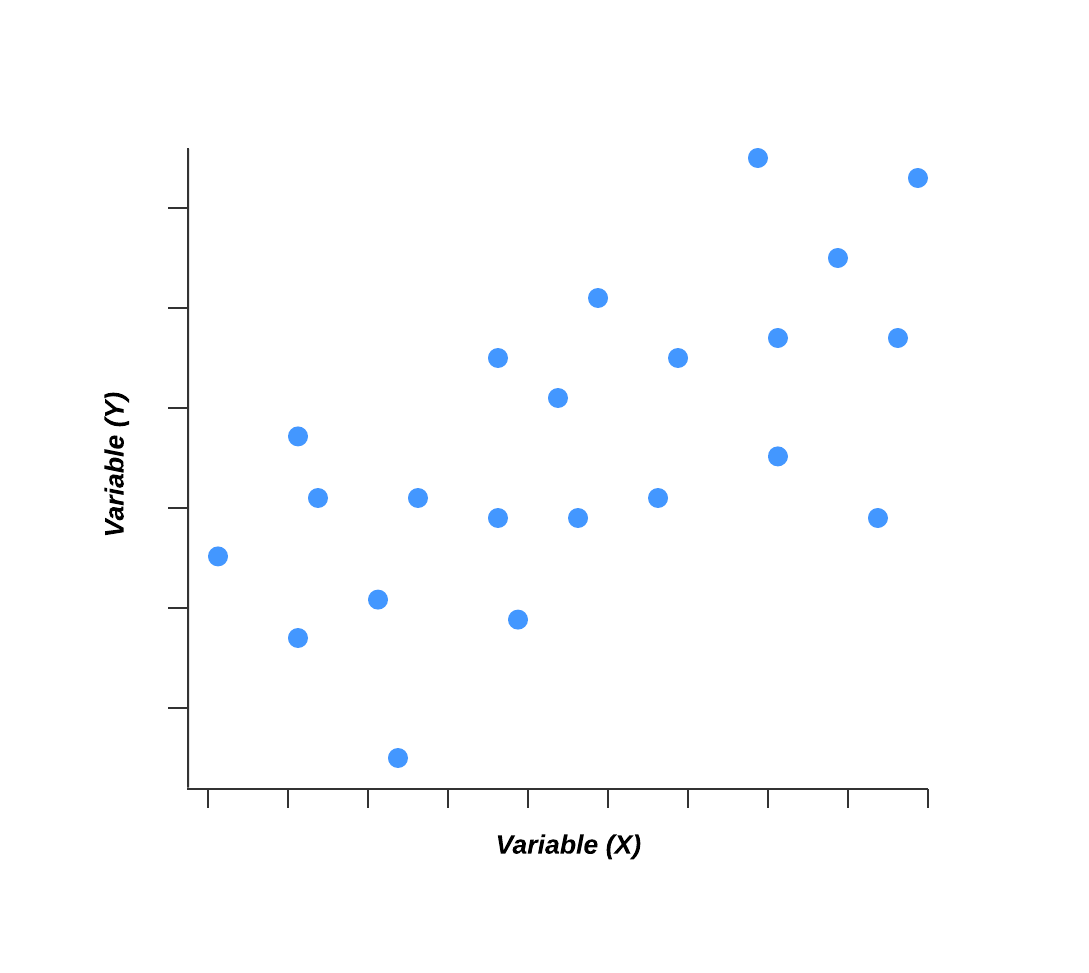

- Design of Experiments: An approach for projects that utilize a structured method of studying variables and outcomes. It may include randomization, established research approaches such as experimental or quasi-experimental, and statistical data analysis.

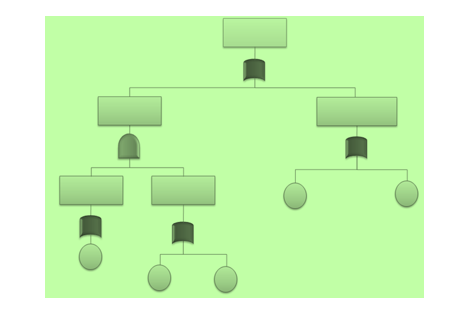

- Cause and Effect Diagrams or Fishbone or Ishikawa Diagrams: A visualization of factors contributing to a given effect, such as prolonged length of stay. [22]

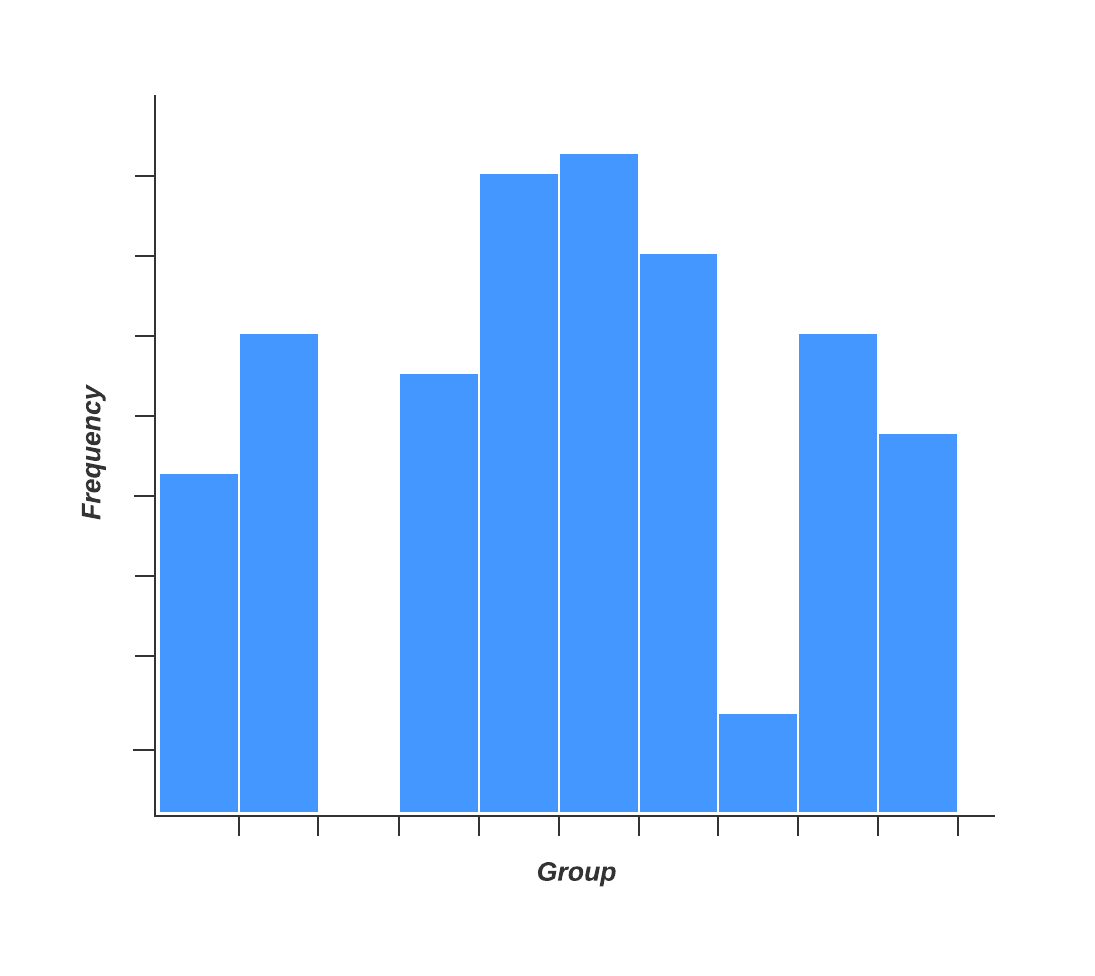

- Control Chart: A graph that shows variation in data relative to a mean value and upper and lower limits.

- Pareto Chart: Stemming from the 80/20 Pareto principle that 20% of factors cause 80% of the problems, is a bar chart showing the frequencies of factors in descending order from left to right to easily identify the most important factors. [22]

- Root Cause Analysis (RCA): A multi-step process of identifying problems, reasons for the problem, and corrective actions after an adverse event occurs.

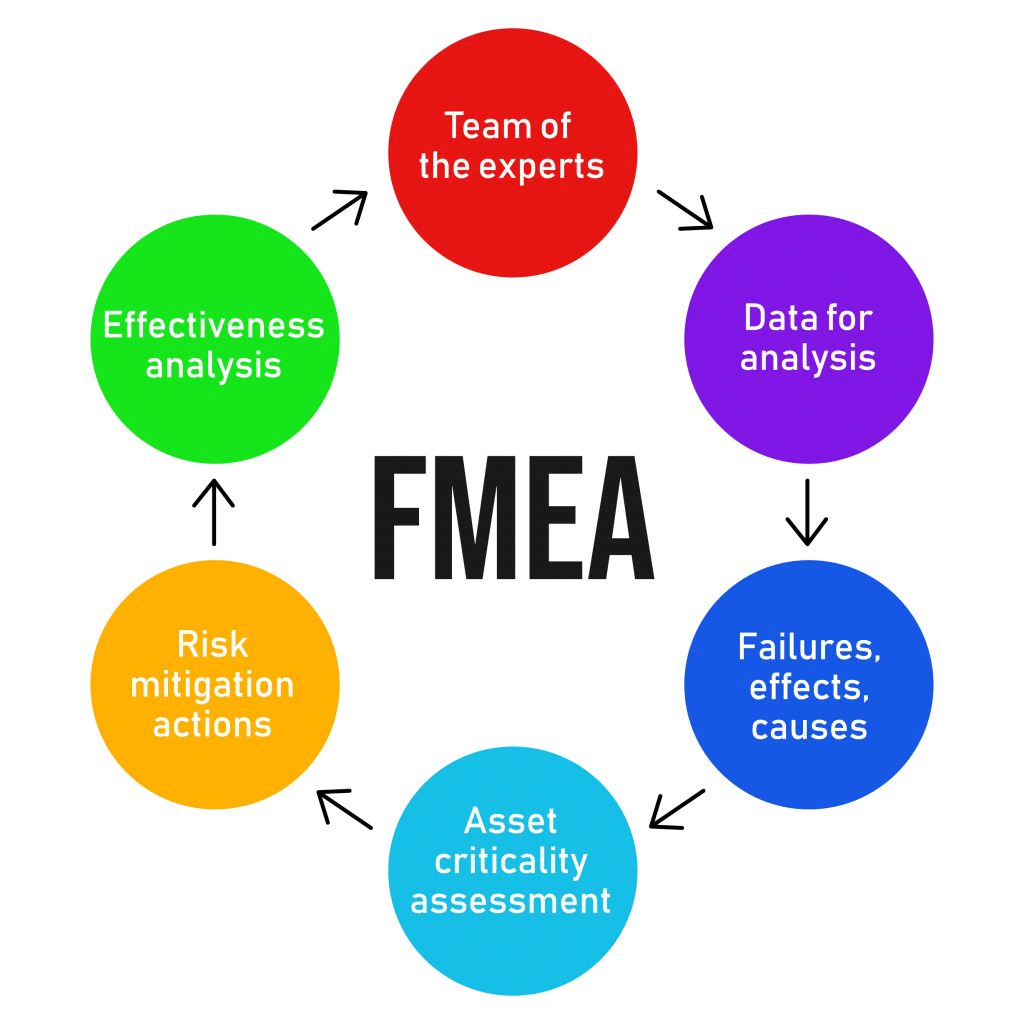

- Failure Mode and Effect Analysis (FMEA): A process of identifying possible failure points in a process as a preventive way to address these weaknesses before they cause problems.

In the early 2000s, the Xerox corporation developed Lean Six Sigma or LSS. [8] LSS marries Lean and Six Sigma approaches and toolboxes and has been used in different business sectors, including healthcare. [8] [17] Successful LSS implementations usually employ waste reduction first before optimization or variability reduction. The healthcare sector benefits from LSS because of reduced waste and cost, improved and optimized processes, and enhanced patient satisfaction in one continuous effort. [23] [24]

- Issues of Concern

Common challenges in Lean methodology include individual resistance to change, discomfort with inter-professional collaboration, and organizational process variations. [25] Methods to overcome barriers include maintaining qualified leadership, obtaining feedback, and pursuing feasible projects. [25] Adequate rollout from senior leadership can be executed by ensuring key stakeholders formally understand Lean practices.

JIT supply chain reduces extra inventory and cost. However, during COVID-19, the lack of supplies, especially personal protective equipment or PPE, exposed the healthcare goal of a slim inventory via reliance on JIT which, during the pandemic, endangered both providers and patients. [12]

PDSA relies on properly executed, small-scale tests before scaling to larger trials. [2] This belief lies in an understanding that small-scale projects are likely to harbor more controlled environments, allowing for more agile pivots upon seeing favorable changes. However, a recent systematic review indicated that fewer than 20% of articles used iterative cycles and small-scale tests, which could suggest that larger tests were not optimal. [2] Another area of concern when enacting a PDSA cycle is pursuing an overzealous, large-scale goal that may lie beyond the method's extent. [3]

A bigger issue with PDSA implementation is oversimplification, which results in projects not fully adhering to PDSA principles. [2] This opens the possibility of incorrect PDSA implementation with inadequate mobilization of resources and skills, jeopardizing scientific rigor. [2] When applying PDSA cycles to healthcare, leadership must ensure adequate resources, including clinical staff, medical technology, inventory, registries, and funding, are present to integrate PDSA cycles into the workflow.

Six Sigma aims to achieve process improvement by decreasing defects and enhancing quality. In healthcare, this often presents as reducing patient harm while increasing patient safety and patient satisfaction. One of the main challenges faced in Six Sigma operations is the cost of hiring a full-time project manager, an in-house expert, or a Six Sigma belt. Another obstacle is the institutional culture, which requires buy-in from all stakeholders for the project's success. This buy-in must last throughout the project duration, which can exceed 24 months in the case of major improvements. [26] While recognized Six Sigma belt certificates can be obtained and offer credible structure, they are not mandatory for process improvement. Formal Six Sigma programs offer training courses, which, combined with field experience, enable certificates to be sequentially obtained (white belt, yellow belt, green belt, black belt, to master black belt). [14] There are concerns that Six Sigma is not being properly used to its full potential in healthcare. [27]

Improving safety culture is critical for long-term quality improvement in healthcare despite challenges in PDSA, Lean, and Six Sigma.

- Clinical Significance

Errors and hazards are present, realistic concepts in healthcare. An extrapolated estimate of over 250,000 deaths based on 2013 hospital admissions occurs in the US annually due to medical errors. [28] Such errors cause losses upwards of $20 billion annually. [28] [29] Excessive wait times and process bottlenecks may lead to delayed diagnoses, treatment, and barriers to appropriate medical triaging. [30] [31] Such outcomes may cause increased patient stress and detrimental effects if delayed reporting is congruent with disease progression, leading to adverse patient outcomes. [30] [31]

Technology in medicine is critical to patient care, allowing centralized team communication, increased patient engagement, and digitized records. Though technological advances such as electronic health records have enabled ease of data acquisition and application of quality improvement functions such as medication allergy alert pop-ups, early rejection and abandonment of technological solutions are seen in healthcare, potentially linked to varied acceptance by users. [32]

The federal healthcare agency Centers for Medicare and Medicaid Services (CMS) has a reimbursement program in healthcare that draws attention to the clinical significance of quality improvement methods in healthcare. [33] [34] The Medicare Value-Based Purchasing (VBP) program uses direct financial metrics to incentivize performance. [33] Metrics include adverse events, mortality, and cost reduction.

This agency evaluates organizations on quality measures and adjusts reimbursement based on metrics, promoting quality improvement and patient care. [34] By adopting quality improvement metrics, healthcare organizations can address patient safety and satisfaction while being mindful of long-term financial and efficiency goals.

- Nursing, Allied Health, and Interprofessional Team Interventions

Quality improvement is a “combined and unceasing effort of everyone – healthcare professionals, patients, and their families, researchers, payers, planners, and educators to make the change that will lead to better patient outcomes, better system performance, and better professional development.” [35]

Interdisciplinary teams used synonymously with interprofessional teams, represent multiple constituents within healthcare working in conjunction with one another. Interprofessional has historically been used more narrowly, signifying working professionals from different professions, while interdisciplinary has traditionally been used more broadly, encompassing distinct healthcare staff members. [36] Adopting interdisciplinary teamwork is critical in healthcare to foster collaboration and diversity, strengthening systemic culture and goals.

One example of quality improvement methods and interdisciplinary teamwork intervention is seen in the Swiss Cheese Model, which was first referenced in 1991 and published in 1997 by psychology professor James Reason. [37] The model compared natural eyes in Swiss cheese to eyes or holes in healthcare systems. Specifically, the holes in healthcare, synonymous with errors, led to adverse events due to an alignment of multiple holes or multiple opportunities for improvement. Each slice of cheese represents a protective barrier, including policies, technology, and teamwork. [38]

Though teamwork is needed in healthcare, it may fail without proper communication, which is a leading cause of inadvertent patient harm, including medication errors, treatment delays, and wrong-site surgeries. [39] [40] Factors influencing communication failure include training differences among health fields, hierarchy, and lack of standardization. [39]

Without mutual collaboration and discussion based on unique perspectives, quality improvement metrics may be prone to fail. By having long-term end goals in mind, such as patient safety, interdisciplinary teamwork can foster quality improvement initiatives. A positive culture of safety does not focus on individual action or error but rather encompasses organizational accountability fostered by teamwork. [41]

- Nursing, Allied Health, and Interprofessional Team Monitoring

Collaborative interaction in healthcare is seen in literature to contribute to improved medical effects. [42] Once an organization adopts the importance of interprofessional team interventions, proper interprofessional monitoring in systematic observation is implemented. A risk management team often achieves such tracking, a set of systems in place to detect, monitor, and prevent harm stemming from the 2005 Congress Patient Safety and Quality Improvement Act. [43]

One example of a risk management intervention is an RCA. [20] The National Patient Safety Foundation recommends an RCA comprising diverse team members ranging from physicians and supervisors to ancillary staff and quality improvement experts. [43] [44] Appropriate monitoring can help maximize quality improvement in healthcare, allowing organizations to effectively utilize quality improvement methods such as LEAN, PDSA, and Six Sigma.

- Review Questions

- Access free multiple choice questions on this topic.

- Comment on this article.

Disclosure: Emily Barr declares no relevant financial relationships with ineligible companies.

Disclosure: Grace Brannan declares no relevant financial relationships with ineligible companies.

This book is distributed under the terms of the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) ( http://creativecommons.org/licenses/by-nc-nd/4.0/ ), which permits others to distribute the work, provided that the article is not altered or used commercially. You are not required to obtain permission to distribute this article, provided that you credit the author and journal.

- Cite this Page Barr E, Brannan GD. Quality Improvement Methods (LEAN, PDSA, SIX SIGMA) [Updated 2024 Jan 11]. In: StatPearls [Internet]. Treasure Island (FL): StatPearls Publishing; 2024 Jan-.

In this Page

Bulk download.

- Bulk download StatPearls data from FTP

Related information

- PMC PubMed Central citations

- PubMed Links to PubMed

Similar articles in PubMed

- Review A framework for healthcare quality improvement in India: the time is here and now! [J Postgrad Med. 2011] Review A framework for healthcare quality improvement in India: the time is here and now! Varkey P, Kollengode A. J Postgrad Med. 2011 Jul-Sep; 57(3):237-41.

- Review The use of Lean and Six Sigma methodologies in surgery: a systematic review. [Surgeon. 2015] Review The use of Lean and Six Sigma methodologies in surgery: a systematic review. Mason SE, Nicolay CR, Darzi A. Surgeon. 2015 Apr; 13(2):91-100. Epub 2014 Sep 2.

- Lean and Six Sigma as continuous quality improvement frameworks in the clinical diagnostic laboratory. [Crit Rev Clin Lab Sci. 2023] Lean and Six Sigma as continuous quality improvement frameworks in the clinical diagnostic laboratory. Thakur V, Akerele OA, Randell E. Crit Rev Clin Lab Sci. 2023 Jan; 60(1):63-81. Epub 2022 Aug 17.

- Review Guiding inpatient quality improvement: a systematic review of Lean and Six Sigma. [Jt Comm J Qual Patient Saf. 2010] Review Guiding inpatient quality improvement: a systematic review of Lean and Six Sigma. Glasgow JM, Scott-Caziewell JR, Kaboli PJ. Jt Comm J Qual Patient Saf. 2010 Dec; 36(12):533-40.

- Review Systematic review of the application of quality improvement methodologies from the manufacturing industry to surgical healthcare. [Br J Surg. 2012] Review Systematic review of the application of quality improvement methodologies from the manufacturing industry to surgical healthcare. Nicolay CR, Purkayastha S, Greenhalgh A, Benn J, Chaturvedi S, Phillips N, Darzi A. Br J Surg. 2012 Mar; 99(3):324-35. Epub 2011 Nov 18.

Recent Activity

- Quality Improvement Methods (LEAN, PDSA, SIX SIGMA) - StatPearls Quality Improvement Methods (LEAN, PDSA, SIX SIGMA) - StatPearls

Your browsing activity is empty.

Activity recording is turned off.

Turn recording back on

Connect with NLM

National Library of Medicine 8600 Rockville Pike Bethesda, MD 20894

Web Policies FOIA HHS Vulnerability Disclosure

Help Accessibility Careers

Problem Solving

– Methodologies and Techniques –

⇓ Introduction to Problem Solving

⇓ What is Problem Solving

⇓ Problem Solving Services

⇓ Learn More About Problem Solving

Introduction to Problem Solving

In the current world market, consumers and organizations have a vast amount of choices regarding the brand or manufacturer of products, parts and materials available to them. In order to not merely survive but thrive in this ever increasingly competitive market, an organization must provide the most value and the highest quality possible. Most organizations have effective quality systems in place. Unfortunately, we cannot always prevent or detect problems before they reach the customer. Whether your customer is a Tier 1 automotive manufacturer or the end user, problems sometimes occur. Even the companies held up as benchmarks for quality in their industry eventually encounter problems with their product or process. The most important factors at that time are how timely and effectively the problem is resolved and prevented from re-occurring. Problems happen so we must be skillful and systematic in resolving the problems as they arise.

What is Problem Solving

Problem Solving is the process undertaken to find solutions to complex or difficult issues by taking an analytical approach using scientific methods. Effective problem solving requires the issue to be recognized and fully understood by the problem solver(s). Then, various problem solving methods and tools can be used to drive down to the root cause of the issue and take appropriate corrective actions to not only fix the problem, but to ensure it does not re-occur. Recurring problems are expensive, drive down brand equity and can damage the supplier / customer relationship. Customers could determine that your organization is not capable of resolving problems within your products or processes. There are many problem solving tools and approaches that are all effective if used properly. The following is a sample list with a brief description of each method.

5 Why is a problem solving method that asks the question “Why” enough times until you get down to the root cause of a problem. The 5 Why exercise can be used as a stand- alone tool or applied within a larger problem solving activity. 5 Why is commonly used during the Analyze phase of the DMAIC process and the Plan phase of the PDCA process. The responses should be based on facts or data and should focus on process or systems errors. The facilitator should ask the team if the cause identified were corrected, could the failure mode or problem still occur. If the answer is yes, then move on to the second “Why” and then the third, fourth, fifth and so on until the answer is no.

Eight Disciplines of Problem Solving (8D)

Eight Disciplines of Problem Solving (8D) is a detailed problem solving method primarily used within the automotive industry but has more recently been utilized by other industries. 8D is typically a team exercise utilized mainly by quality engineers or managers and other professionals. The 8D approach employs statistical analysis of the process and stresses the importance of determining the root causes of the problem. The basic elements of the 8D method are to identify the problem, form a team, determine root causes, develop corrective actions, both interim and permanent, and ultimately, to prevent the problem from reoccurring. It is also an effective tool for use during product and process improvement initiatives.

The A3 Report has its roots in the PDCA method. The A3 Report format is an effective tool for communicating all pertinent information with greater visual impact. A3 gained its name from the size of paper used during the exercise. By literally writing and drawing it all out on one sheet, it clearly communicates what is being done at each step of the problem solving activity improving team communication. The A3 format is a valuable problem solving and critical thinking tool that can foster continuous improvement.

Corrective Action Preventive Action (CAPA)

Corrective Action Preventive Action (CAPA) is usually part of an overall Quality Management System (QMS) . The Corrective / Preventive Action process is generally a documented procedure used to collect and analyze information, identify any non-conformances and take appropriate action (corrective or preventive) to resolve problems and prevent recurrence. The CAPA process closely follows the PDCA methodology of Plan, Do, Check, Act. The use of data to drive actions is prevalent in most CAPA systems. In some cases, Statistical Process Control (SPC) data is incorporated into the process. Corrective actions are directed at eliminating known causes of failure or other product or process issues. Preventive actions are derived from structured risk analysis and focused on eliminating the cause of a potential failure.

Is / Is Not

The Is / Is Not tool is adaptable in that it can be used as a stand-alone problem solving tool or by establishing boundaries during a larger problem solving activity using one of the methodologies discussed above. It may be used to define the problem and determine the scope of what will be considered and what will not be considered during the problem solving exercise. The Is / Is Not simply asks the questions about the problem and determines what the problem is and is not. For example, a manufacturer starts getting feedback from their dealers of a particular problem. By entering the answers to the questions in a basic diagram, you can identify the scope of the problem and then determine where to apply resources and focus on the real problem.

The Is / Is Not tool produces results by allowing you to focus on the facts of the problem, and specifically on the boundaries created by determining what is and is not involved. Your team can then focus their efforts and attention on the likely causes and take action.

Plan Do Check Act (PDCA)

Plan-Do-Check-Act (PDCA) is also sometimes referred to as the Shewert circle is an excellent method for problem solving or continuous improvement. The basics of the PDCA cycle are to Plan or identify the problem. Do or perform a process study or root cause analysis to determine cause and potential improvements. Check or measure the results of the corrective action or improvement. And then Act, take action based upon the results of the study. The PDCA is not a straight line but a circle or cycle. Once the actions have been validated then use the knowledge acquired to plan additional improvements and begin the cycle again.

No matter which method you select, they all have some basic steps in common. The problem must be defined, the root causes identified, effective temporary and permanent countermeasures put in place, the results measured, monitored and validated. Through this process, you can resolve a problem and prevent recurrence. While problem solving methods are valuable tools in your quality toolbox, some of them can be applied to a product or process before a failure occurs or during a continuous improvement initiative (i.e. Kaizen ). By using these tools, a potential failure may be foreseen, analyzed, and actions can be taken to prevent the failure from ever occurring. Tools such as Failure Modes and Effects Analysis (FMEA) , both Design FMEA and Process FMEA , can be utilized to reduce the likelihood of failures occurring.

Problem Solving Services

At Quality-One, we offer many services directed at helping you resolve any current problems or prevent problems from occurring. Our experienced team of highly trained professionals will provide a customized approach for developing your people and processes based on your unique problem solving needs. At Quality-One our services include:

- Consulting to provide assistance or guidance in developing a plan to deploy a new problem solving initiative

- Training to help your teams understand and drive improvement

- Support in building and implementing your selected problem solving process, which may include Facilitation, Auditing and / or Contract Services

Learn More About Problem Solving

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of Problem Solving Consulting, Problem Solving Training or Problem Solving Project Support.

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

Discover your potential savings with our ROI Calculator

8D Management (8 Disciplines Management)

8D Management & The 8D of Problem Solving

Problems are a part of life and a business is no exception. Even with the best of intentions and systems, some errors can creep in and be hard to detect. It may be nothing serious or can have serious repercussions such as reputation damage, heavy fines, product recall, property loss, and so on. It becomes essential to identify the problem, its consequences on the one hand, and causes on the other to be able to not only resolve it for now but also ensure prevention of its recurrence. One of the methodologies, popular amongst engineers and professionals mainly in the automotive industry but now applied across several industries is the eight disciplines (8D) model. It helps to identify, correct, and eliminate recurring problems, affecting improvement in product and process.

Related Assets

Whenever organizations tackle problems and generate solutions based out of root cause analysis, they tend to generate a lot of…

Key Highlights: 8D is an extremely effective, proven problem-solving framework, especially in the manufacturing and automotive sector. However, to truly…

From a quality management standpoint, a problem may be reported in an organization from one of the following processes: Complaints…

What is 8D?

The 8D is a systematic, holistic and proven methodology designed to identify the root cause of a problem, plan a quick fix, and implement corrective actions and preventive actions to avoid their recurrence. If your product is defective or not meeting your customer requirements, then 8D is an excellent first step to improve Quality and Reliability.

One of the core parts of introducing 8D problem solving, greatly accepted by most disciplines of industries, and having huge effectiveness levels in improving product and process quality, would be 8D (Eight Disciplines). Key steps in the 8D methodology are forming a team, defining the problem, identifying and implementing interim containment, identifying the root causes, implementing and verifying permanent corrective actions, and avoiding future recurrence of problems. The 8D process for root cause analysis concludes by highlighting that the team members not only play a vital role but also recognizes them, hence reinforcing that this approach is a collaborative one. 8D has become very popular among manufacturers, assembly, and services around the globe because it is effective and comparatively easy to teach.

Introduction to 8d Problem Solving

The 8D approach to problem-solving, also known as the 8D methodology, is a systematic and comprehensive method used to address and resolve complex issues, particularly in manufacturing and other industries.

This 8D troubleshooting methodology involves a structured process designed to identify, correct, and prevent issues, ensuring that similar problems do not occur in the future.

By following the 8D process steps, teams can effectively perform root cause analysis and implement corrective actions.

The 8D structured problem-solving process is highly valued for its ability to provide a clear framework for identifying and eliminating the root cause of a problem, thereby enhancing overall operational efficiency.

Why to Apply 8D Problem Solving Methodology?

The 8D methodology , developed to represent the best practices in problem solving, provides the engineering teams with an effective and efficient team-oriented problem solving skill, a better understanding of Root Cause Analysis (RCA) and how to use basic statistical tools required for problem solving. 8D helps the management understand and resolve problems better, identify necessary systemic changes and inputs for change, and facilitate a more candid and open communication in problem solving discussions.

8D improves the Quality and Reliability of your products, and if performed correctly, prepares the engineering team for future problems.

When to Apply 8D Problem Solving Process?

The 8D problem solving process is used to solve major, critical, chronic, and recurring problems. The 8D is typically required during safety or regulatory issues, customer complaints , warranty concerns, poor performance or test failures, internal rejects, and to minimize waste and scrap.

How to Use Root Cause Analysis to Transform Your Safety Program

8d problem solving approach.

The 8D is a systematic process for the introduction and improvement of quality, and elimination of problems. Here we will show you the step by step approach of the problem solving tools that can make you proficient at identifying causes of problems, defining problems, and errors. Additionally, it helps identify root causes and take actions to solve and prevent identified problems in processes. So, let’s take a peep inside:

D0: Planning and preparing for the 8D

Proper planning and preparation are always a good start before taking any action. So, you need to consider the following before forming a team:

- Problem description

- Timeframe for the resolution

- The number of resources to accomplish this

D1: Team establishment

Create a team with people who varied backgrounds and experiences which will lead to the best quality inputs and a complete solution. For the team to function smoothly, define clear roles, and responsibilities for your people, and have a team leader.

D2: Problem description

The 8D method’s primary focus is to describe the problem appropriately and objectively such that it captures all the vital information. During this analysis, repeated 5W1H (why, what, who, where, when, and how) are required to be asked to develop a clear description.

D3: Problem containment plan

A temporary problem containment plan is sometimes needed to minimize the impact of the problem until you develop permanent solutions. On developing the plan based on the hypothetical cases, the resources for addressing the main problem can be released. At times, new processes may be required to work around the problem until you have a permanent fix.

D4: Root Cause Analysis (RCA)

With the problem temporarily contained, you can now turn to identify all of the root causes of the nonconformance . There are several tools to identify the actual root cause of an issue including the 5W1H to understand the problem in-depth, Fishbone diagrams to visually categorize causes, and Pareto charts to identify the vital causes.

D5: Permanent Corrective Action

Once the root cause of the problem is determined, the team can start brainstorming permanent corrections to identify what the best long-term solution will be. Brainstorming sessions combined with tools such as affinity diagrams help organize ideas based on their relationships and determine the best course of action.

D6: Implement and Validate the Permanent Corrective Action

Once the solution is identified, the management needs to implement and verify the corrective action using the PDCA (plan-do-check-act) approach for small-scale testing before large-scale rollout. Thus, the outcomes and corrective actions are tracked to ensure expected results. To successfully implement a permanent change, a project plan should incorporate:

- Development of the project plan for implementation

- Communicating the plan to all stakeholders

- Validating improvements using measurement

D7: Prevent Recurrence

A complete solution of problems means preventing them from occurring. Besides, preventative measures should also be implemented for corrective actions in the 8D methodology. This requires reviewing management processes, operating procedures, and training manuals to ensure that best practices are followed.

At this stage, organizations should consider actions including updating process audit questions and regularly verifying them based on corrective actions to reduce risk in other processes, presenting poka-yoke or error-proofing devices to big-risk processes, and conducting red rabbit tests to see how long it takes poka-yoke devices to detect defective product.

D8: Verification and Team Celebration

Once the problem is solved, the ultimate step is to congratulate the team. It’s important to recognize their efforts and share their success across the organization because teams require feedback to allow for satisfactory closure. This facilitates motivation and employee engagement while helping you improve quality control, execute process improvements, and aid change management as you grow.

Create a team with people who are having varied backgrounds and experiences which will lead to the best quality inputs and a complete solution. For the team to function smoothly, define clear roles, and responsibilities for your people, and have a team leader.

A complete solution of problems means preventing them from occurring initially. Besides, preventative measures should also be implemented for corrective actions in the 8D methodology. This requires reviewing management processes, operating procedures, and training manuals to ensure that best practices are followed.

8D Root Cause Analysis (RCA) and 8D Corrective Action Process

The 8D Root Cause Analysis, as well as the 8D Corrective Action process, is a widely systematic approach in quality management , especially concerning 8D in quality control. This method includes eight comprehensive steps that are devised to problem solving by dealing with root causes of the problems comprehensively. The steps of the 8D process start with the formation of a team, a clear definition of the problem, and move on to interim containment actions. This is then followed by detailed root-cause analysis using the 8D RCA process, development and verification of permanent corrective actions, implementation, and recurrence preventing efforts. Encouraging details in the analysis: the 8D methodology steps encompass collaborative efforts and documentation that ensure durable solutions and continuous improvement in organizational processes. Root Cause Analysis (RCA) is embedded within the 8D process and includes the following steps and techniques:

Problem Symptom is measured and transformed to “Object and Defect”

Problem Symptom is reformed to Problem Statement using the 5W1H process

Potential Causes are gathered using the tools like Fishbone or Affinity Diagram

Problem Statement should fit using both the “is” and the “isn’t” sections of the question

Root Cause concepts are developed from remaining possible causes on the tool and related changes from is/is not

Compare theories with recent data and develop experiments for Root Cause Verification

Test and confirm the Root Causes

Customer Success

3 Women Leaders Making a Powerful Impact in Global Quality and Safety Management

How to use the 8d approach.

8D portrays 8 steps of a structured approach to solve difficult, recurring, or critical problems by providing transparency, driving a team approach, and increasing the chances of solving the problem.

Proper plan for solving the problem and identify the prerequisites.

Team creation

Gather a cross-functional team with product/process knowledge.

Problem description and definition

Use the data and information to specify the problem by identifying in quantifiable terms the who, what, where, when, why, how, and how many (the 5W1H) for the problem.

Problem Containment Plan development

Develop and implement interim actions to eliminate the problem from any customer in the future.

Specify and assess Root Causes

Identify and review all relevant causes and sources of variation that analyze why the problem has occurred and figure out why the problem was not noticed at first using 5W1H or diagrams.

Verify Permanent Solutions

After collecting data confirm that the possible solutions will actually resolve the problem.

Implement and Validate Corrective Actions

Discuss and review results and develop plans to implement the best solutions or countermeasures.

Preventive measures

Transform the operation systems, management systems, procedures, and practices to avoid the recurrence of similar problems.

Compliment your team

Recognize the collective efforts of your team and formally thank them for their involvement.

8D Problem Solving Tools and Techniques

The 8D problem solving methodology is the set of tools and methods aiming for complex quality issues. 8D problem solving techniques are basically comprised of a fishbone diagram, 5 Whys analysis, Pareto charts, process flowcharts, and Failure Mode and Effects Analysis (FMEA) to come to terms with the 8D framework. Integration with statistical tools and data analysis in every step of 8D analysis is sure to make the most accurate identification of the root cause.

This approach would ensure that cross-functional teams' participation would not only be present in the brainstorming sessions but also in the 8D problem solving process at the problem solving stage.

Training in 8D Methodology

8D training is an inevitable imperative that makes its deployment in organizations effective. The 8D methodology provides all the necessary details that the teams could apply to the skills and knowledge required at every step in 8D of quality control . Training the workforce on 8D methodology will make them able to apply these aspects when dealing with real-world problems, which will better off the quality and efficiency of the entire organization. It ensures that all these measures and strategies have been inducted to make sure that 8D problem solving approaches are not just tools for problem solution but have been inducted to lay down the base for sustainable quality improvement and prevention practices in the organizational processes.

How to Enhance Quality and Efficiency in 8D Manufacturing?

Understand the Basics of the 8D Approach to Problem Solving

- Familiarize yourself with the principles of the 8D methodology.

- Recognize that the 8D process steps include team formation, problem

Form a Cross-Functional Team

- Assemble a team with diverse skills and perspectives.

- Ensure each member understands their role in the 8D structured problem solving process.

- Use precise language to describe the problem.

- Implement tools like the 5 Whys to aid in the root cause analysis 8d problem solving phase.

Implement Interim Containment Actions

- Take immediate steps to prevent the problem from worsening.

- Document these actions as part of the 8D troubleshooting methodology

Identify and Verify Root Causes

- Conduct a thorough root cause analysis to pinpoint the underlying issues.

- Utilize techniques like fishbone diagrams and Pareto charts in the 8D RCA Process.

Develop Permanent Corrective Actions

- Propose solutions that address the root causes identified.

- Ensure these solutions are sustainable and prevent recurrence.

Validate the Corrective Actions

- Test the solutions to ensure they effectively resolve the problem.

- Collect data to confirm the effectiveness of the root cause analysis and the 8Dd corrective action process.

Implement and Monitor Solutions

- Roll out the verified solutions across relevant areas.

- Continuously monitor the impact to ensure long-term success.

Prevent Recurrence

- Update processes and documentation to incorporate the new solutions.

- Train employees on the new procedures to embed them in daily operations.

Recognize and Celebrate Success

- Acknowledge the efforts of the team in solving the problem.

- Use this opportunity to reinforce the importance of the 8D methodology in maintaining quality and efficiency.

Ensuring compliance with FDA regulations is crucial for medical device manufacturers to maintain market access and ensure patient safety. Medical Device Compliance Software plays a pivotal role in helping companies align with these stringent requirements. Here’s how:

Great product, support, and people to work with!

We have rolled-out CQ across our company to automate various elements of QMS requirements such as Document Management, Complaints, Non-conformances, Corrective Action (8D and A3), Supplier Management and Audit Management. We have been using the software for more than 2 years. We are glad to see how well the system is being used across the company. We have several thousand users on the system currently and working to scale the usage further. CQ solution has been configured to meet our needs, works elegantly across languages, across time zones, and business verticals. With integration between CQ and SAP to exchange critical data, the process automation provides a lot of productivity.

CQ configuration team and support have worked hard to ensure that our needs continue to be met. They consistently go above and beyond. We cannot be more pleased with our use of CQ QMS capabilities and would definitely recommend to anyone who is looking for a modern cloud based EQMS solution especially if you want a scalable EQMS solution.

Lia Budiman, Continental Contitech

8D Process Improvement in Different Industries

Automotive Industry

- Application of 8D Methodology : Essential for addressing recurring quality issues and customer complaints.

- Root Cause Analysis 8D Problem Solving : Identifies underlying issues affecting vehicle performance and safety.

- 8D Structured Problem Solving: Used to enhance manufacturing processes and reduce defects.

- 8D Process Steps: Followed rigorously to maintain high safety and quality standards in vehicle production

Aerospace Industry

- 8D Troubleshooting Methodology: Critical for resolving complex technical issues and ensuring compliance with stringent safety regulations.

- 8D RCA Process: Applied to investigate and eliminate root causes of system failures.

- 8D Corrective Action Process: Ensures that preventive measures are implemented to avoid the recurrence of problems.

- 8D Manufacturing: Focuses on precision and reliability in the production of aerospace components.

Electronics Industry

- 8D Approach to Problem Solving: Used to tackle issues related to product design and manufacturing.

- Root Cause Analysis and the 8D Corrective Action Process: Vital for maintaining product quality and reducing warranty claims.

- 8D Process Steps: Helps in identifying and addressing defects in electronic components and assemblies.

- 8D Methodology: Ensures continuous improvement and innovation in electronics manufacturing processes.

Healthcare Industry

- 8D Structured Problem Solving: Applied to improve patient care and operational efficiency in healthcare facilities.

- 8D Problem-Solving Steps: Utilized to address issues related to medical equipment and procedural errors.

- Root Cause Analysis 8D Problem Solving: Enhances patient safety by identifying and eliminating causes of medical errors.

- 8D Troubleshooting Methodology: Ensures that corrective actions are taken to prevent the recurrence of adverse events.

Food and Beverage Industry

- 8D Manufacturing: Ensures product quality and safety throughout the production process.

- 8D Approach to Problem-Solving: Addresses contamination issues and improves production line efficiency.

- Root Cause Analysis and the 8D Corrective Action Process: Essential for maintaining food safety standards.

- 8D Process Steps: Used to investigate and resolve quality issues in food production systematically.

Pharmaceutical Industry

- 8D Methodology: Applied to ensure the consistency and safety of pharmaceutical products.

- 8D RCA Process: Identifies and addresses root causes of deviations in manufacturing processes.

- 8D Corrective Action Process: Implements preventive measures to ensure compliance with regulatory standards.

- 8D Troubleshooting Methodology: Enhances production efficiency and reduces the risk of product recalls.

Consumer Goods Industry

- 8D Structured Problem Solving: Used to resolve product design and manufacturing issues.

- 8D Process Steps: Ensures consistent product quality and customer satisfaction.

- Root Cause Analysis 8D Problem Solving: Identifies and eliminates causes of defects in consumer products.

- 8D Manufacturing: Focuses on improving production processes and reducing waste.

Energy Industry

- 8D Approach to Problem Solving: Applied to address equipment failures and improve operational reliability.

- Root Cause Analysis and the 8D Corrective Action Process: Ensures the continuous improvement of energy production processes.

- 8D Troubleshooting Methodology: Helps resolve complex technical issues in energy plants.

- 8D RCA Process: Identifies and eliminates causes of energy generation and distribution inefficiencies.

8D Process Metrics and KPIs

- Problem Resolution Time: This metric tracks the time taken from problem identification to resolution in the 8D root cause analysis process, ensuring timely corrective actions are implemented to prevent recurrence.

- Recurrence Rate: By measuring how often a similar problem reappears after the 8D corrective action process, this KPI helps assess the effectiveness of the implemented solutions and continuous improvement efforts.

- Root Cause Identification Accuracy: This KPI evaluates the precision and accuracy with which the root causes are identified during the 8D root cause analysis, ensuring that the correct issues are being addressed.

- Corrective Action Implementation Rate: This metric tracks the percentage of corrective actions successfully implemented within the stipulated timeline, indicating the efficiency of the 8D corrective action process.

- Customer Satisfaction Improvement: Monitoring changes in customer satisfaction levels following the 8D corrective action process can highlight the impact of the process on overall product quality and customer perception.

8D Problem Solving Report

8D problem solving reports and templates are useful tools to initiate a problem solving process. These reports are used to explain what 8D is and including information about each step so that one will know what needs to be done by attempting this to solve problems. Keeping these reports easily available can avoid repeating work on the same problems over and over again.

8D reports must be detailed and incorporate information at every step within the 8D process. Those who are working on the problem should provide sufficient information when completing a report so that someone who was not on the current 8D team can pull it out and understand what the problem was and what solutions were implemented.

Improve quality, eliminate problems and identify the root cause of a problem with 8d Methodology

Who can 8d help.

The 8D methodology is universally applicable for every organization that needs solving. Although, there are a few industries and sectors where this 8D approach is successfully used such as manufacturing, the automotive industry , engineering companies that manufacture products or parts, and medium and large-scale enterprises.

Related Checklists

Quality Assurance Checklist – Part A (Project Management)

Checklist | September 7th, 2022

Quality Assurance Checklist – Part B (Project Deliverables)

Quality Control Area Safety Audit Checklist for Pharmaceutical Companies

Checklist | April 22nd, 2022

Implementing the 8D Root Cause Analysis

Establish the Team

- Assemble a cross-functional team: Ensure diverse perspectives and expertise.

- Define roles and responsibilities: Clarify each member's contributions.

- Team leader selection: Choose someone with strong leadership and problem-solving skills.

Describe the Problem

- Problem statement creation: Define the issue clearly and concisely.

- Use of data and evidence: Gather and present data to illustrate the problem.

- Scope and impact: Detail how the problem affects processes, products, or customers.

- Immediate actions: Implement temporary measures to contain the problem.

- Verification of ICAs: Ensure the containment actions are effective.

- Monitoring: Continuously monitor the situation until a permanent solution is found.

Determine Root Causes

- Root cause analysis techniques: Utilize tools like the 5 Whys and Fishbone diagrams.

- Data analysis: Examine data to identify patterns and anomalies.

- Identify multiple root causes: Look beyond the obvious to find all contributing factors.

Develop Permanent Corrective Actions (PCAs)

- Brainstorm solutions: Generate potential corrective actions.

- Evaluate effectiveness: Assess the feasibility and impact of each solution.

- Select the best solution: Choose the most effective and sustainable corrective action.

Implement and Validate PCAs

- Action plan creation: Develop a detailed plan to implement corrective actions.

- Execution: Carry out the corrective actions according to the plan.

- Validation: Verify that the corrective actions resolve the problem effectively.

- Standardization: Update processes, procedures, and documentation to include the new solutions.

- Training: Educate employees on the new procedures to ensure consistent application.

- Monitoring and review: Regularly review the effectiveness of the implemented solutions.

Recognize the Team and Celebrate Success

- Team recognition: Acknowledge the contributions of each team member.

- Celebrate achievements: Celebrate the success of solving the problem.

- Document lessons learned: Record insights and lessons learned for future reference.

Quality-centric Companies Rely on CQ QMS

Frequently Asked Questions

The 8D methodology is often used since it provides a consistent, simple, and thorough approach to solving raised problems at various stages. If properly applied, it gives several advantages such as:

A systematic approach for improving team-oriented problem solving skills

A clear understanding of basic statistical tools needed for problem solving

A practical understanding of the ‘ root cause analysis’ tool

Creating and expanding relative information about past failures and lessons learned to avoid future problems in the organization

Improving skills for corrective action deployment

When the team is trying to find the root cause of the problem and deploy corrective actions, some defective products will continue to be manufactured. To prevent these defective parts from reaching the customer, interim containment ensures that the defects are contained in the facility till the problem is completely solved. If defective parts reach the customer, it may result in warranty claims, field failures, and customer complaints.

To implement the 8D process successfully, the following factors are crucial:

The right team

An accurate description of the problem

Avoiding skipping through steps

Ensuring cooperation within the team and management support

Understanding the difference between real causes and possible causes

Related Insights

5 Dos and Don’ts When Choosing a QMS Solution for Your Enterprise

Every investment a business makes should have a measurable impact. In the case of an EQMS, the ROI is based…

Root Cause Analysis – Definition, Benefits and Process

All Quality and Safety Management Standards emphasize the importance of…

5 Why vs. Pareto Chart vs. Fishbone Diagram – Pros and Cons of Each of These RCA Techniques

All Quality Management Standards emphasize the importance of identifying the…